A nice picture on a Taylorcraft L2-m on display during the second world war. I am not sure of the origin of this image.

A year long mystery has been solved!

I am trying to finish up all the fuselage details on the L2-M, in order to apply the interior fabric, give it a final shot of paint, and then begin the final assembly! Over the last year, I have been spending my limited available hours replacing the old copper fuel lines with aluminum, fitting the header tank (part of the fuel system), installing the control surface cables, and making a new instrument panel (dash board).

One thing I could not figure out was the fuel shut-off control linkage. OK, hang with me for just a minute. The fuel system is gravity fed from two tanks in the wings. Fuel lines run down to the header tank (mounted behind the instrument panel), then to the engine. There is a shut-off valve on the header tank connected to a handle on the control panel located left of the pilot seats. All the linkage and the handle was missing!

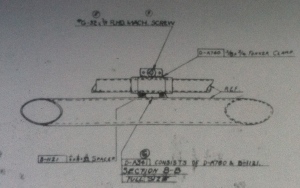

In 1945 this aircraft was “civilianized” when it left the military. The greenhouse (the glass canopy over the cockpit), spoilers in the wings, rear swivel seat and map desk, radios, and the fuel shut-off linkage were all removed. Not only was the linkage removed, the clamp system that held it all in place had been cut off. I had no idea what it looked like! I could build the linkage, but had no idea how to attach it to the fuselage. I had no luck with any google searches or any of the email requests I sent out . My first break through came when, reading the “Erection and Maintenance Manual” (-2), where it mentioned how to replace the fuel shut-off linkage and its attachment with two “Fokker Clamps”. I could see the where the clamps had been cut off the fuselage, but still could not make sense of how the whole thing went together. When looking through the the blue print cds I found the before overlooked images! As I have mentioned in previous posts, there is not a reliable index for these blueprints. You have to go through each of the hundreds of prints looking for possible fits.

Next job was to build the clamps! My first attempt was a failure. I used chromoly steel which was too hard and cracked while installing it. With help from my neighbor metal worker Nate, we bent up some softer steel, and a little custom welding from the master Scott Draper, I now have a working fuel shut-off system!

The freshly bent soft steel for clamps. I had to drill holes for a machine screw, and rivit on a nut plate

This was a long time coming. I do love these little mysteries, and the paths they lead me on. More updates to follow!